Our customized formulations range from Acne treatment, Wrinkles, Stretchmarks, Vitiligo, Scar, Rosacea, Hair loss treatment patches for targeted bald areas and patches for chemical peels. We offer topical patches in doses ranging from 10 MG up to 100 MG, with adhesives that are flexible, breathable, and removable.

AmWiner is an ISO 13485 certified contract manufacturer of hydrogels and transdermal patches, pharmaceutical and cosmetic and transdermal patches with additives. We work with customers whose concepts are in all stages of development from conceptual through full production. We help customers create prototype samples, manufacture complete product lines, warehouse, and direct ship products to fulfilment centers. We work with companies to design and manufacture small and large transdermal and topical patch die cuts that meet the most stringent health and safety standards. We work with small start-up companies as well as large, well-established companies to help them get their medicinal patches onto the market.

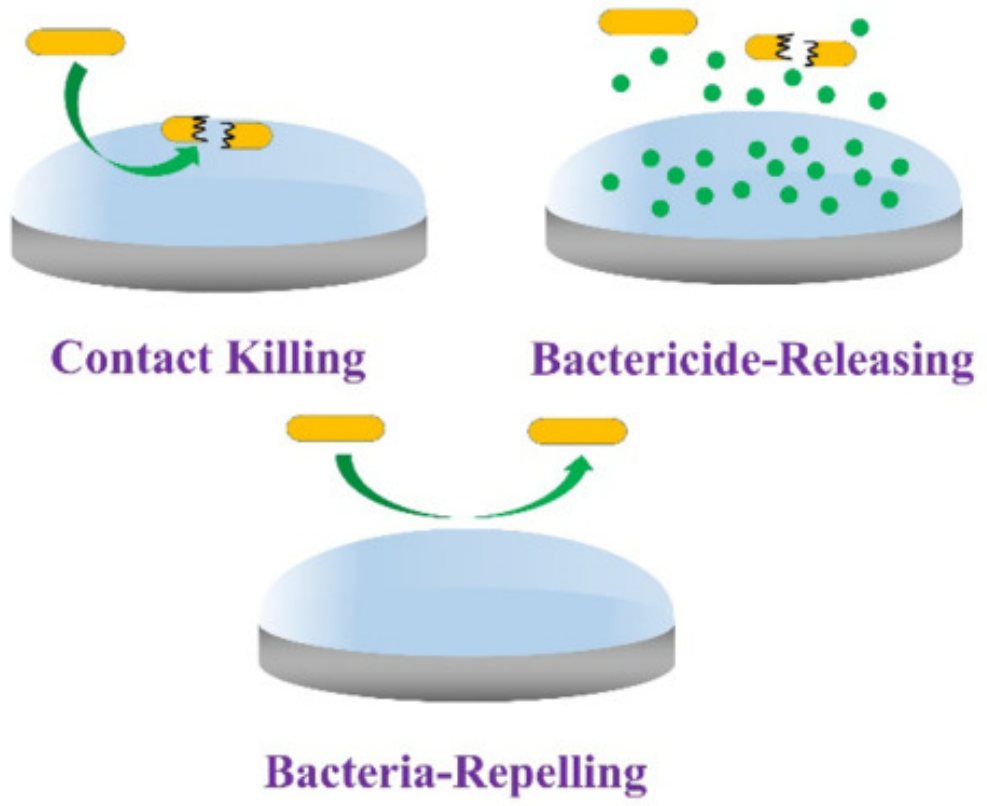

We offer customized product development, prototyping, and stability testing capabilities. We will help design your product to be manufacturable and cost effective and conduct extensive testing procedures for your product to guarantee efficacy and active ingredients dermal delivery and develop a new formula from scratch or change our existing liquid formula to custom hydrogel or hydrocolloid patch, and integrated other ingredients such as antibacterial agents, cosmetic agents, Minoxidil, menopausal aid, pain killers, active pharmaceuticals, and your choices.

The production of transdermal patches is a continuous process that consists of 3 stages that reflect how delicate and specific the production of this niche pharmaceutical form. The process consists of the following stages:

• Mixing of the active ingredients

• Coating, Drying and Laminating

• Die-cutting and Packaging.

It represents the beginning of the manufacturing process, and its objective is to achieve the integration of the active and non-active ingredients that make up the formulation. The first step is to fraction and weigh each of the materials that will be part of the mixture, according to what is established in the production methodology.

At this stage it is important to control the correct dissolution and dispersion of the components to guarantee the homogeneity of the adhesive mixture necessary to ensure the correct dosage and that all the units produced are effective and safe because of the controlled release of the active ingredient.

Coating, Drying and Laminating

Once the mixture is obtained, the following process consists of three sub-stages: first is the coating, which is a continuous process where the mixture is uniformly dispensed on the release liner, then both components go through various drying stations to evaporate the volatile components of the mixture, in order to obtain the “adhesive mixture”.

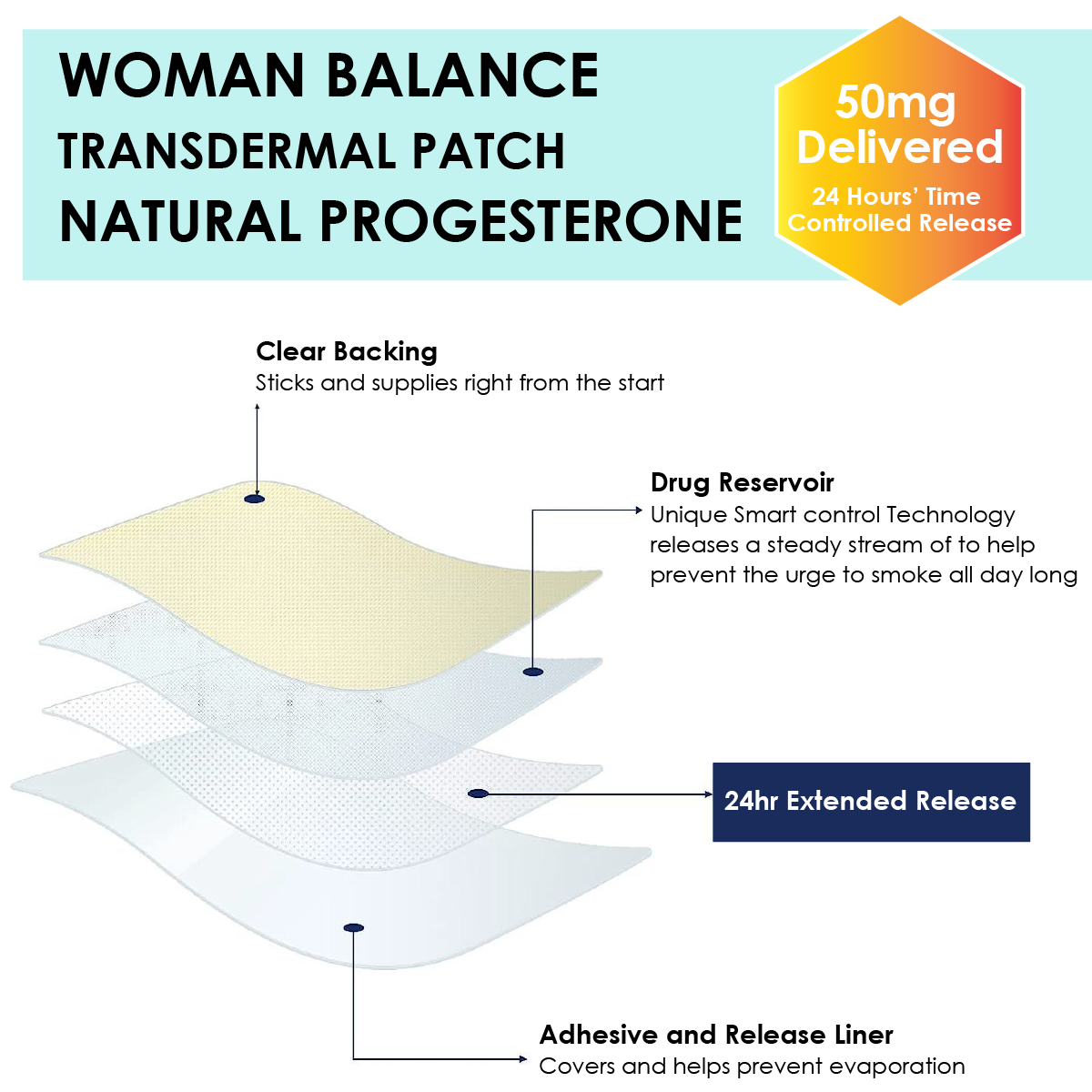

Finally, both components are joined at the exit of the drying stations with the backing film, thus obtaining the multilayer system that forms the transdermal system. At this stage, it is important to control the weight of the adhesive matrix dispensed per unit area and the adhesive properties of the matrix, that way, a correct adhesion of the patch at the place of application and a correct dosage of the drug is guaranteed, and consequently the safety, efficiency, and quality of the drug.

The next and last process is the die- cutting and packaging of the transdermal patches. In this stage, the shape of the patch itself is obtained with the surface established according to the dose. This process is carried out by die cutting the layers obtained in the previous process where several cuts are generally made, one of them being the cut for easy detachment, therefore allowing the patient to open the patch and then to apply it on the safer and more practical area of the skin.

One size does not fit all in dermatology medicine. AmWiner supports dermatologists seeking the right custom medicines to target a diverse set of patients and skin conditions. Mass-produced products have many inactive ingredients and potential allergens that may not be compatible with everyone. AmWiner is committed to abiding by The Drug Quality and Security Act (DQSA) which, is intended to ensure that the highest quality of drugs are produced under cGMP. We not only abide by governing regulations but seek to set new benchmarks for compliance and excellence. Our company ensures that consumers continue to have access to the safe and effective custom products they need. Every product we produce is with our commitment to benefit health and wellbeing.

Hydrolyzed Keratin Hair Particles Fibrils with 2% Biotin & 0.1% Microcrystalline Minoxidil Sulphate. Raphe brand Keratin Hair Fibrils are made with two ingredients: keratin (99.9 %) and Crystalline Minoxidil Sulfate 0.1% for men and Keratin 98% with 2% Biotin for Women, formulated to treat hair loss at the same time cover the loss area while waiting for the natural hair to regrow. Each bottle contains 0.024cm desiccant balls to keep the hair strands dry, preserve the material, and prevent clumping.

No silica anti-caking agent, no Cetrimonium Chloride, and no DMDM Hydantoin. Not made with Gossypium Herbarium Powder, Cotton, or Sodium Chloride but pure Hydrolyzed Keratin amino acid. This is the main difference from other hair fibers made from vegetal materials such as cotton, or made from synthetical material such as rayon, nylon. Due to their composition looking unnatural, fall, clump, and easily shift away or onto the scalp.

Deriving from a 100 % natural plant source with no additional chemical chemicals. Raphe keratin fibers are crystalline hydrolyzed keratin amino acid fibrils, with 70-micron size per fibril, have a texture and appearance identical to the natural hair, guaranteeing the best quality when compared to other fibers available on the market.

Directions: After applying the Minoxidil foam or solution, roll the micro-derma roller over the scalp to drive the ingredients in, then sprinkle the Keratin Minoxidil/Biotin hair fibers and use the fiber-holding spray to bond or securely lock the fibers in place. This makes it resistant to water, rain, and wind and prevents the fibers from coming off or being rubbed off till you intentionally wash your hair with shampoo.